Zu Mission-LC Mk.III adds Teflon™ into the insulation/dielectric mix, as well as pure silver to a percentage of the conducting circuits. Mission-LC Mk.II did not use Teflon™ or silver. Mission-LC Mk.III is a high conductance, linear impedance, mainly copper conductor loudspeaker-level cable designed and built to define the standard for affordable high-end hi-fi loudspeaker cables.

The majority of design and testing was performed at the Spectra Sonics building, 3750 Airport Road, Ogden, and on a healthy number of solid-state and P-P and SET vacuum tube amplifiers. Loudspeakers used in testing included Focal, Tannoy, the huge Sound Labs and a slew of Zu loudspeakers, from Method Bookshelf to Dominance. We are confident in Mission-LC Mk.III loudspeaker cable’s ability to improve your system’s dynamic agility without highlighting or emphasizing problems in recordings or your playback room and system. Mission-LC Mk.III has excellent resolution and has a tone center right smack in the middle of the music-weighted power spectrum.

Cable Design

The field geometry of Mission-LC Mk.III are built on a signal and power transmission technology originating with Nikola Tesla, an electrodynamics format that allowed for very wide bandwidth and large power transmission. Within the cable’s E&M architecture we combine pure U.S. refined and drawn copper and silver. Dielectrics include the careful use of a bit of Teflon, used on a few of the circuits to improve treble detail and stereo realism without messing up tone. Mission-LC Mk.III has a very supple hand, understated looks and un-inflated size. And yes, we build it to last several lifetimes.

Directionality

Mission-LC Mk.III is not a permanently directional cable; it can be used in either direction. However, we pay close attention to direction of manufacture, from wire to cable, and identify this by placing the writing of the cable data barrels so it reads in the direction of signal travel—from amplifier to loudspeaker. Connecting it like this ensures matching channel fidelity, increased burn-in speed, and allows easy direction identification after cable or gear swapping.

Burn-in

Mission-LC Mk.IIII will require a good bit of play before it reaches full performance. Nevertheless, it should sound excellent right out of the box. If you wish to accelerate the burn-in, know we DO NOT recommend any special burn-in devices or special recordings. We do recommend music you enjoy, preferably upbeat full spectrum recordings: rock, roots, full orchestra, big band.... For the possible how and whys about burn-in please see our Answers section.

Maintenance & Cleaning

Connector maintenance and cleaning is covered above. The cable itself doesn’t show dust or fingerprint and shouldn’t require cleaning. Still, spills and pets happen, Mission-LC Mk.III can be cleaned with any common household cleaner.

Termination and Connections for Mission-LC Mk.III

Connectors serve several functions—facilitating easy hookup of your gear being primary. But close to easy of use is the need for good electrical and mechanical connection over time and under your environmental conditions. Since this is a home audio product, the environment is assumed to be your home, which is not as uniform as you might initially think. Those that live on or near the coast contend with salt air, which significantly increases corrosion rates. But even if you don’t live “close” to the sea, say you live as far as a mile [1.6 km] from the coast but still get a sea breeze, you could notice the effects of sea air. Some connections need maintenance, others don’t. Here’s an overview of the termination offered for Mission-LC Mk.III.

Spades [Forks]

Spades offered for Mission-LC Mk.III are the new universal Kimber Kable spade. They are made from pure copper and rival the Zu spades we have been making from copper welding lugs since 2000. The universal Kimber Kable spade fit both standard 1/4” [6.3mm] and oversized 5/16” [8mm] shafts. They are also thin enough to work with plastic encapsulated binding posts, the ones that require you to slide the spade through a slit in the plastic. This spade is as good a spade as you can get, equaling the performance of the WBT Nextgen Cu spade. The Ultraplate(R) version (silver in appearance) of the universal Kimber spade is extremely resistant to even direct salt spray and requires no scheduled maintenance. The unplated (raw copper) version does require you to clean as you would bare wire.

Maintenance Schedule / Plated Version - None

Maintenance Schedule / Unplated Version - These require inspection and cleaning. How often depends on where you live and the mechanical qualities of the connection. High desert dwellers should inspect and clean them every time they are disconnected and reconnected, or every five to ten years. Those living right on the seaboard should inspect and clean the spades every time they are disconnected and reconnected, or twice a year. Those living within a mile or so of the sea [a kilometer or two], but without much of a sea breeze should make cleaning them an annual habit. For everyone else, every other year is enough. We recommend Cape Cod Polish for copper, silver and plated contacts.

Banana Plugs

Mission-LC Mk.III is offered with Kimber Kable banana plugs. ITT/Pomona has been making these for Kimber Kable since the late 1970’s. They are about as good as you can get, are highly corrosion resistant, and they are mechanically tough—if you need banana plugs, these are among the very best.

Maintenance Schedule - None

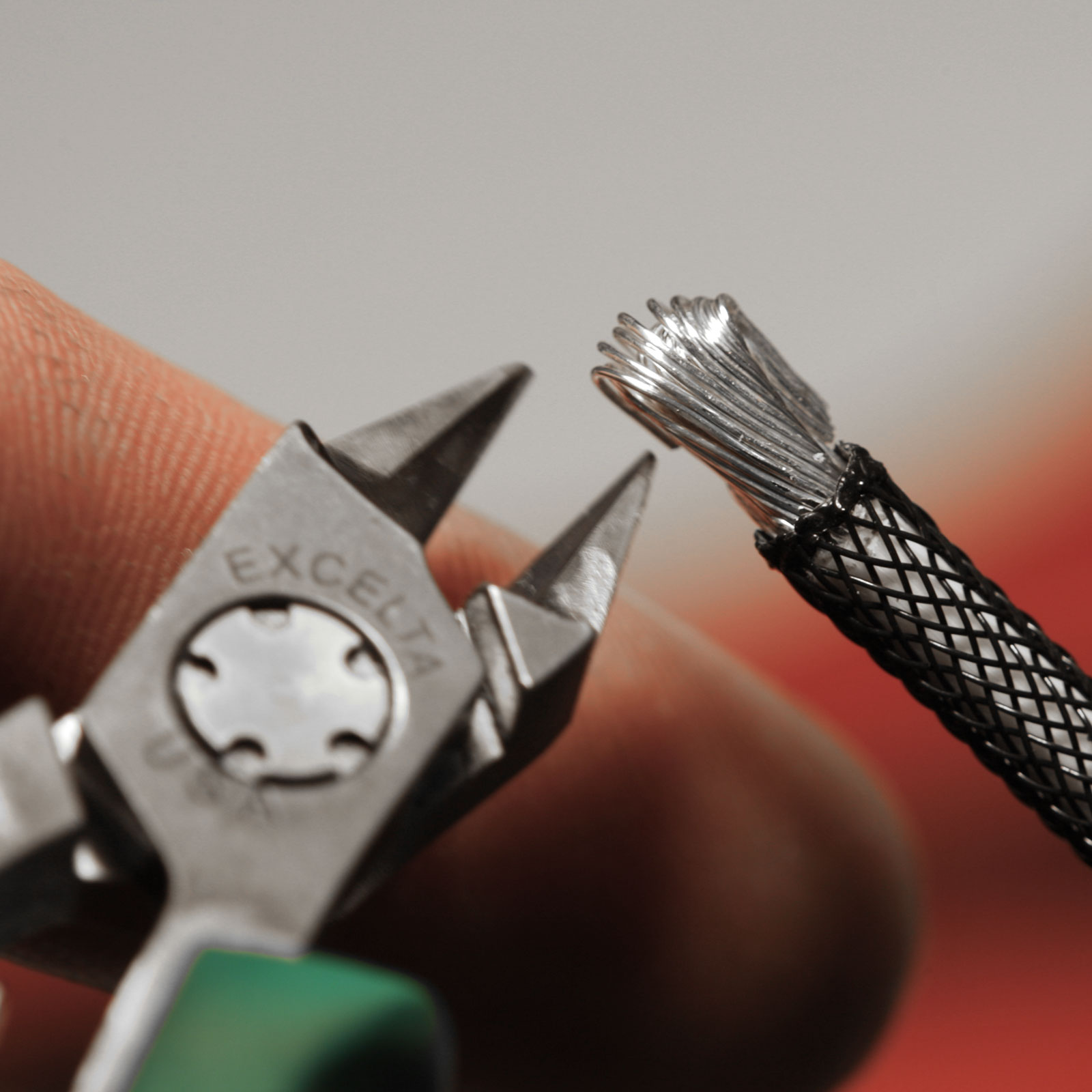

Bare Wire

Bare Wire on Mission-LC Mk.III is prepped with 3/4” [19mm] lead-out length and has the tips “tinned” with 4% silver bearing lead-free solder.

Pros - Bare wire has the best conductivity (DCr) generally. And as there’s no wire-side connector, bare wire is less money. In some situations, the mechanical flexibility offered by bare wire connection is desirable.

Cons - Bare wire can be a bit fiddly to connect up, particularly in tight spaces. Bare wire connections require maintenance as they are more susceptible to corrosion.

Maintenance Schedule - Bare wire requires inspection and cleaning. How often depends on where you live and the mechanical qualities of the connection. High desert dwellers that have a good bare wire connection should inspect and clean the bare wire ends every time they are disconnected and reconnected, or every five to ten years. Those living right on the seaboard should inspect and clean the bare wire ends every time the ends are disconnected and reconnected, or twice a year. Those living within a mile of the sea, but without much of a sea breeze should make it an annual habit. For everyone else, every other year is enough. We recommend Cape Cod Polish for cleaning bare wire.

ZuB3

ZuB3 termination is the ideal connection for Zu loudspeakers that feature this connection. The connection is as conductive as bare wire, and has electrodynamics profiles that best matches Zu speaker cables and speakers. The connection is also resistive to corrosion and self cleaning—every time you break and make a connection the contacts are wiped clean. More about this connection is found here. The ZuB3 connection is only offered at the speaker end.

There are no cons to this connection save a bit of cost, and the size of the connector if you are needing to run the cable through an opening in the wall or furniture.

Maintenance Schedule - None