Libtec Loudspeaker Cable

Zu Libtec, despite its humble size, is a high conductance loudspeaker cable designed to compliment all hi-fi and studio loudspeaker/amplifier applications. It excels in match ups as diverse as very low power vacuum tube/very high efficiency loudspeaker pairings as well as ultra power hungry high current combinations. Libtec has a very linear and uniform tone response and will not hide problems in a system, yet will not introduce or reveal unwanted character either. If you like the sound and timbre of your system, but you are looking for increased top to bottom resolution with improved stereophonic recreation and possibly increased dynamics and texture, Libtec is your solution.

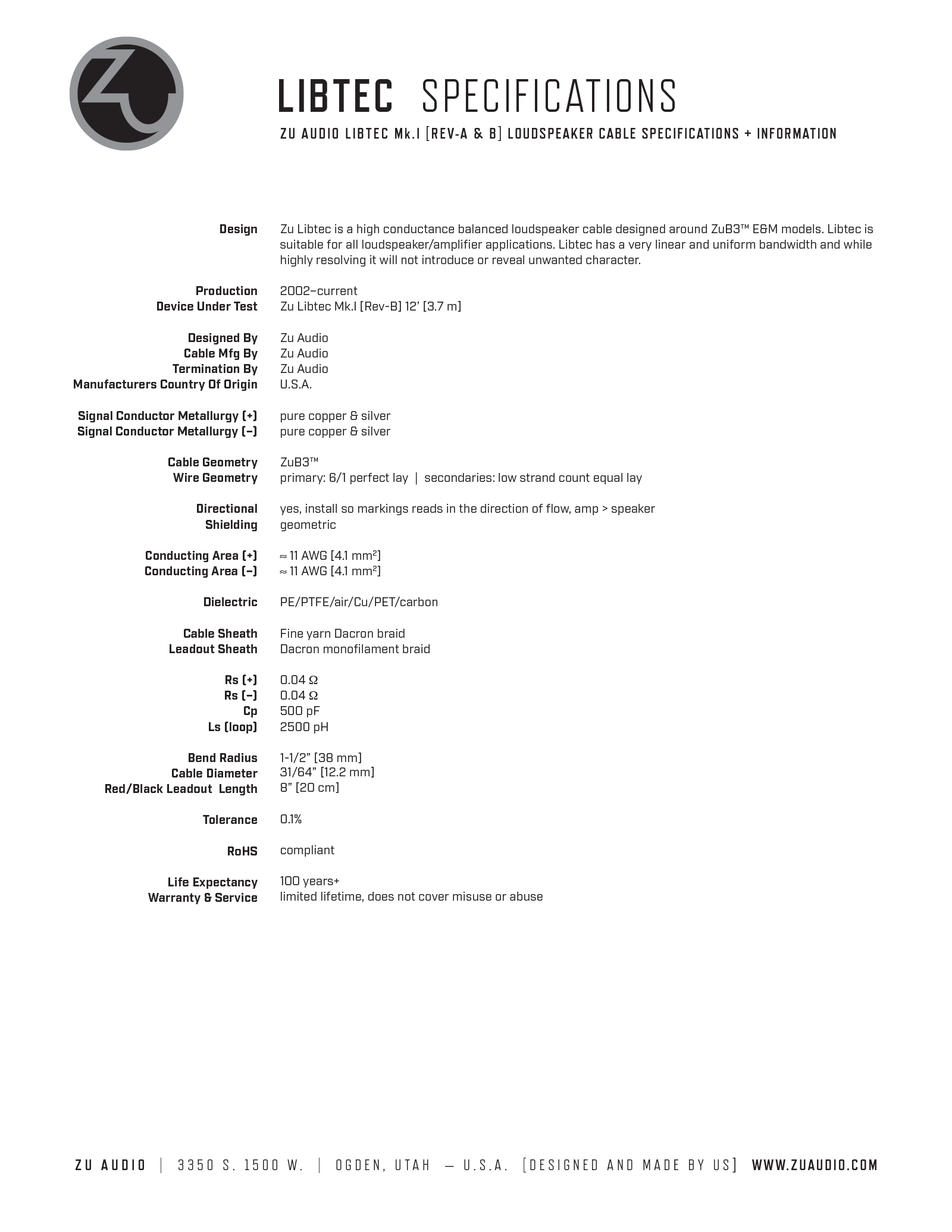

Quick Specifications

Production: 2003–current

Manufacturer: Zu Audio, Ogden, Utah, USA

Archetype: ZuB3

Metallurgy: pure copper & silver

Dielectric: PE/Teflon/air/Cu/carbon/PET

Conducting Area: 11 AWG [4.1 mm2] (each charge, balanced)

Rs: 0.04 Ω

Cp: 500 pF

Ls: 2500 pH

RoHS: compliment

Libtec Ad Copy + Complete Tests & Measures PDF Download

Price is for a matched pair (one left/one right). Please let us know connector needs with your order. Singles are simply half price.

Burn-in

Libtec will require a good bit of play before it’s fully burned in, roughly 400 hours—a healthy use of Teflon® equals slow burn-in. We do not recommend any burn-in devices or special recordings. We do recommend music you enjoy, preferably upbeat full spectrum recordings: rock, roots, full orchestra, big band.... For the possible how and whys about burn-in please see our Answers section.

Libtec Maintenance

No maintenance is required for the cable or the connectors save for the annual copper spade cleaning. If your connector contacts are nice and bright, don’t worry about it. However, anytime you are making an electrical connection make it a habit to inspect the contacts and clean them if they are tarnished or dirty.

Instillation Notes

Switch your power amp off prior to disconnecting or connecting your loudspeaker cables.

Now, wash your hands with soap prior to handling any cable with bare metal—you don’t want to push halides and other subtle tone robbers into the amplifier, cable or loudspeaker connectors. If you do touch the exposed contacts you might want to buff them with a clean cotton rag. Keeping the contacts free of contaminants ensures a long-term and trouble-free connection.

To clean plated connectors, shinny bright gold or silver colored ones, just use rubbing alcohol on a cotton cloth and some cotton swabs to get into the tight parts. If the connector being cleaned is bare copper or silver we recommend cleaning them with our favorite polish, Cape Cod™.

Anytime you are making an electrical connection make it a habit to inspect the contacts and clean them if they are tarnished or dirty. Our bare copper spade lugs may need to be cleaned every year, depending on how clean they are when connected and your environment. Most any copper polish will work for this though we have found Cape Cod™ to be excellent. Brasso™ is also good. Acid based cleaners are tricky, if you don’t have experience cleaning copper with acid we wouldn’t recommend that you start with your audio gear. Most of the time your terminals are going to be in good condition and just need a little buffing and for that you can use a bit of alcohol and a cotton cloth.

Libtec History

Libtec was our second loudspeaker cable to feature our ZuB3™ E&M cable design; the first was Wax which was introduced a year or so prior, back in 2001. Wax was an all copper conductor design and didn’t use any exotic insulation materials. With Libtec we wanted to reduce noise and improve bandwidth and linearity of capacitive and inductive reactance which were realized with further revisions to the conductive circuits characteristic impedance as well as dielectrics.

Q: How about the name Libtec, where did that come from?

A: Libtec is a compound of Liberace and technology—a clever way to say you are really good at making stuff with your hands. We love the expression, it resonates with us, still does. Back in those early days our cable machine was primitive, plywood and bent steel, and required more human power and elbow grease than electricity. Liberace technology was not coined by us, we stole it from Mike Olson, founder of Mervin Manufacturing (Lib Tech & Gnu snowboards). Not sure if Mike coined it but it’s a great name.

Libtec is Zu’s only cable to have been manufactured in all locations: Sean’s garage, The Historic Ogden Kiesel Building, the Old Ogden Post Office, Zu Plant Nº 1 and now Zu Plant Nº 2, both in the Ogden Commercial Industrial Park. In Sean’s garage cable was made on our original planetary cable machine that Adam Decaria designed and built from common materials: plywood, aluminum and steel. While this was primitive it could lay down high precision cable, just not all that fast. Current Libtec cable making machine was designed and built by Randy Sandman back in 2006. Randy’s machine is a precision, servo controlled planetary machine capable of high precision and high production and likely to remain in service for a very long time (Randy always does it right, and always over builds). Thephoto herein is Randy and his newly finished semi-automated planetary machine c. summer 2007. Manning the machine and production of Libtec cable is nearly exclusively James Read. Termination and quality assurance has been controlled by Cable Superstar Stefanie Casey since 2010—you can thank her for the cables stunning fit and finish and overall build quality.

Libtec has remained essentially unchanged since introduction and has been a very effective tool for us in hooking new customers.